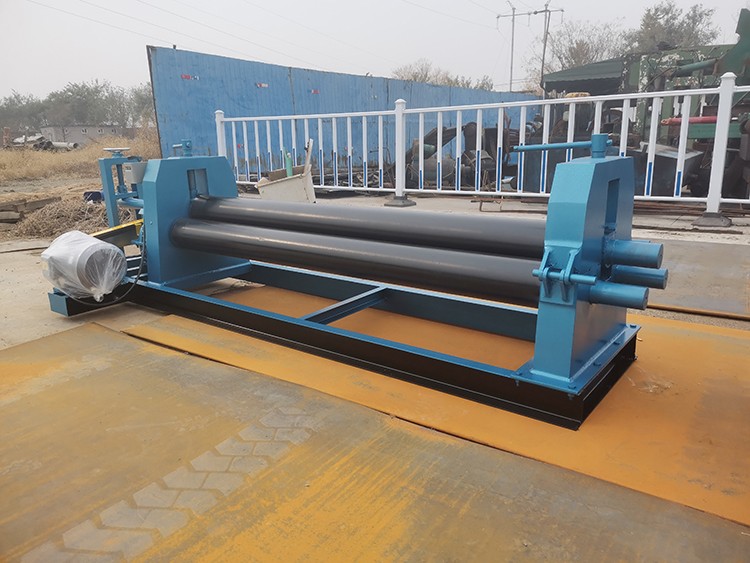

We are a professional plate rolling machine manufacturer with over 10 years of industry experience. Today, we would like to introduce to you the support program for large diameter cylinder processing by plate rolling machine:

In the field of machinery manufacturing, large diameter cylinder machining is a common process. This type of workpiece usually refers to cylindrical structural parts with a diameter of more than two meters, which are widely used in pressure vessels, reaction towers, pipelines and other equipment. Due to their size and weight, special support solutions are required during machining to ensure stability, safety and machining accuracy.

1, Principles of support scheme design

There are three basic principles to be followed in the design of the support program. Stability, the support system must be able to withstand the weight of the workpiece and cutting forces, to avoid vibration or displacement during the machining process. Adjustability. Since large cylinders may have slight ellipticity or uneven wall thickness, the support device must have height and position adjustment. Safety, all support points must be force calculated and anti-tipping devices must be installed.

2, Commonly used support methods

Roller support system

This system consists of several active or passive rollers arranged in a polygonal shape to support the cylinder. The active rollers can drive the workpiece to rotate and are suitable for turning. The surface of the rollers is usually covered with an elastic material such as polyurethane, which increases friction and protects the surface of the workpiece. Each set of rollers is equipped with a separate motor drive and frequency conversion speed control to ensure synchronized operation. This type of support allows the cylinder to rotate continuously and is suitable for external round machining.

Fixed bracket support

Steel welded curved brackets lined with wood or nylon pads are used. The curvature of the bracket matches the outer diameter of the cylinder, and the height is fine-tuned by hydraulic or mechanical jacks. Each bracket is equipped with a locking mechanism to fix the position of the workpiece during machining. This solution is suitable for segmental machining or welding operations, and can effectively control the axial runout of the cylinder.

Combined support

A hybrid solution combining rollers and fixed carriers. Normally, fixed carriers are used in the machining area to ensure stability, while auxiliary rollers are used in the non-machining area to facilitate workpiece adjustment. This design combines positioning accuracy and ease of operation and is particularly suitable for the segmental machining of very long cylinders.

3, Configuration of auxiliary devices

A complete support system requires several auxiliary devices. The centering device is used for initial positioning and ensures that the cylinder axis is concentric with the machine spindle by means of a laser or mechanical pointer. Anti-deformation supports, especially necessary for thin-walled cylinders, are usually of the internal bracing type to counteract the deformation caused by the cutting forces. A safety wheel is mounted on the outside of the support to prevent accidental side-slip.

4, Installation and commissioning points

Before installing the support system, clean up the foundation plane to ensure that the support points are at the same level. After initial seating, use the latitude and longitude meter to detect the straightness of the cylinder busbar. After rough machining, the support status should be recalibrated to eliminate the deformation caused by cutting stress release. For precision machining, it is recommended that vibration sensors be arranged at the support points to monitor system stability in real time.

5, Special working conditions

When machining the cylinder with flanges or tabs, additional auxiliary support is required at the shaped structure. For large diameter cylinder welded on site, modular hydraulic support system can be adopted to adjust the support point flexibly according to the position of weld seam. When working in high temperature environment, heat-resistant alloy support parts should be used to avoid thermal expansion affecting the positioning accuracy.

6, Maintenance and inspection

Regularly inspect the mechanical components of the support unit for wear and tear, with emphasis on bearings, gearing mechanisms and locking devices. The hydraulic support system should keep the oil circuit clean and replace the filter element regularly. Electrical parts should be well treated against dust and moisture. Before each use, carry out no-load test run to verify the coordination of the moving parts.

Reasonable support program can not only ensure the machining quality, but also extend the service life of the equipment. The actual selection needs to comprehensively consider the size of the workpiece, processing technology, site conditions and other factors. With the development of CNC technology, the modern support system has gradually realized automatic control, real-time adjustment of support force distribution through the force feedback system, which provides a new solution for the processing of oversized diameter cylinder.

If you are interested in plate rolling machine, please contact us.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com