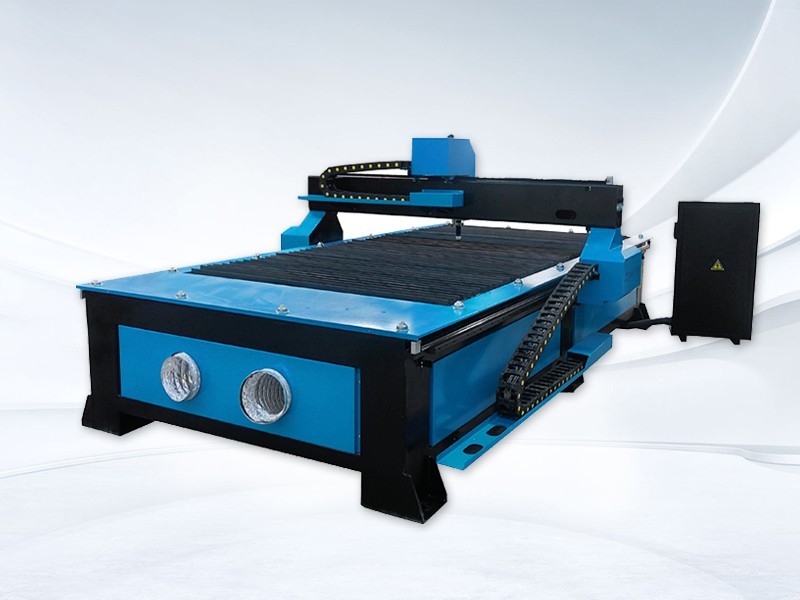

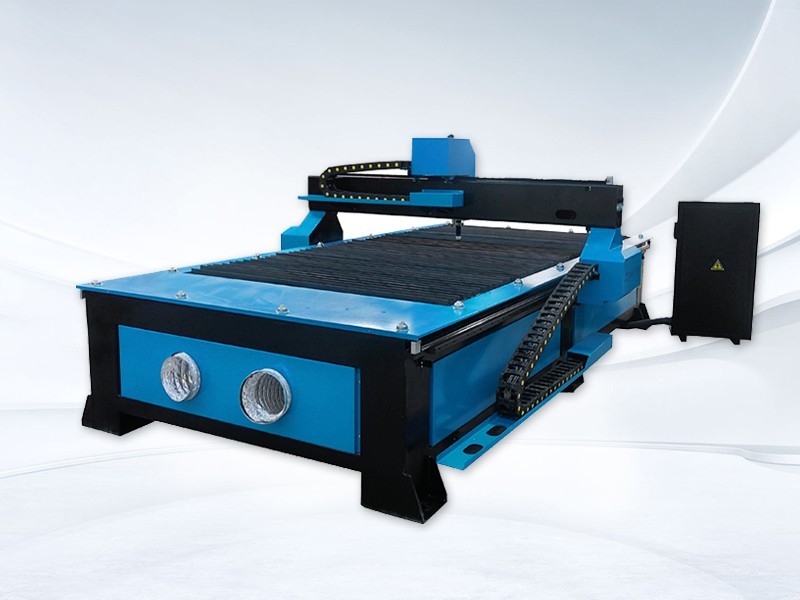

In the field of metal processing, CNC plasma cutting machines have become an indispensable core equipment in modern manufacturing due to their high efficiency, precision, and strong adaptability. It achieves rapid melting and cutting of metal materials through high-temperature plasma arc, and is widely used in industries such as automobile manufacturing, shipbuilding, steel structure construction, energy equipment, etc. This article will systematically analyze the working principle of CNC plasma cutting machine from three dimensions: energy conversion mechanism, core component collaboration, and cutting process control, and explore its technical advantages and development trends.

1.Energy Conversion Mechanism

1.1 Power System: The Starting Point of Energy Conversion

The power system of a CNC plasma cutting machine is the "heart" of the entire equipment, with its core function being to convert alternating current into direct current and provide continuous energy for the stable combustion of the plasma arc. Modern CNC plasma cutting machines commonly use inverter power technology, which achieves high-frequency switching control through IGBT (Insulated Gate Bipolar Transistor) modules. It converts 50/60Hz AC power into high-frequency AC power, which is then rectified and filtered to output stable DC power. This design is not only small in size and light in weight, but also has an energy conversion efficiency of over 90%, significantly reducing equipment energy consumption.

1.2 Gas Compression and Ionization: The Birth of Plasma

The formation of plasma arc depends on the ionization process of compressed gas. Numerical control plasma cutting machines usually use compressed air as the working gas (nitrogen, oxygen, or mixed gas can also be selected), which is transported to the inside of the cutting torch through pipelines. In the cutting torch, the gas flows through the nozzle and is heated by a high-speed arc. The electrons in the atoms gain enough energy to break free from the atomic nucleus and form a plasma composed of free electrons, positive ions, and neutral particles. This process requires two conditions to be met: first, the gas temperature needs to reach several thousand degrees Celsius, and second, there needs to be a strong enough electric field to maintain the ionization state.

1.3 Compression and Focusing of Plasma Arc

The energy density of plasma arc directly affects the cutting quality. To improve energy concentration, the CNC plasma cutting machine adopts a triple mechanism of mechanical compression, electromagnetic compression, and thermal compression:

Mechanical compression: By reducing the diameter of the nozzle outlet and limiting the diffusion range of the plasma arc, it forms a slender cylindrical arc column.

Electromagnetic compression: Utilizing the Lorentz force generated by the interaction between current and its own magnetic field to further compress the diameter of the arc column and increase the current density.

Thermal compression: The thermal expansion effect generated by the high-temperature plasma itself opposes external constraints, further reducing the diameter of the arc column.

After triple compression, the energy density of the plasma arc can reach 10 ⁶ -10 ⁷ W/cm ², and the temperature exceeds 20000 ℃, which is sufficient to instantly melt any conductive metal.

2.Collaboration of core components

2.1 Numerical Control System: The "Brain" of Cutting Process

The numerical control system is the core control unit of the CNC plasma cutting machine, which automates functions such as cutting path planning, speed control, and arc voltage adjustment by receiving G-code instructions generated by CAD/CAM software. Modern CNC systems generally adopt an open architecture, supporting multi axis linkage control, which can accurately control the movement trajectory of the cutting torch in the X, Y, and Z directions, and adjust cutting parameters in real time to adapt to different materials and thicknesses. For example, when cutting thick plates, the system will automatically reduce the cutting speed, increase the current and air pressure to ensure the quality of the cut; When cutting thin plates, the arc pressure and gas flow rate are optimized to reduce the heat affected zone and avoid workpiece deformation.

2.2 Torch Structure: Terminal for Energy Transfer

The cutting torch is a component that directly interacts with the plasma arc and the workpiece, and its design directly affects the cutting accuracy and efficiency. A typical cutting torch structure includes components such as electrodes, nozzles, vortex rings, cooling water jackets, etc

Electrode: usually made of high melting point materials such as hafnium and zirconium, responsible for guiding the arc and maintaining its stability.

Nozzle: By precision machining, a small outlet is formed, which cooperates with the electrode to form a plasma arc channel, while withstanding high temperature and high-speed airflow erosion.

Vortex ring: Utilizing the centrifugal force generated by gas rotation to further compress the plasma arc and increase energy density.

Cooling water jacket: It removes the heat generated by the cutting torch through circulating cooling water to prevent component overheating and damage.

2.3 Gas Supply System: Ensuring Cutting Quality

The gas supply system is responsible for providing stable working gas for the plasma arc, and its performance directly affects the cutting effect. Modern CNC plasma cutting machines commonly use multi-stage gas regulating valves, which can accurately control gas flow and pressure, and switch gas types according to cutting process requirements. For example, when cutting stainless steel, using nitrogen as the working gas can reduce the formation of oxide layers; When cutting carbon steel, oxygen is used to enhance the oxidation reaction and increase the cutting speed.

3.Cutting process control

3.1 Arc initiation stage: establishment of stable arc

Arc initiation is a crucial step in the cutting process, and its stability directly affects the quality of the incision. Numerical control plasma cutting machines usually use high-frequency arc ignition technology, which generates high-frequency electric sparks between the electrode and nozzle through a high-frequency oscillator, and breaks down the gas to form an initial arc. Subsequently, the system controls the gas flow rate and current to gradually transfer the arc to the surface of the workpiece, forming a stable cutting arc. To avoid arc initiation failure, modern equipment is also equipped with arc voltage detection and automatic arc restart function, which can quickly reignite the arc after it is extinguished, ensuring cutting continuity.

3.2 Cutting Stage: Dynamic Balance of Energy and Materials

During the cutting process, the heat of the plasma arc rapidly melts the metal at the cutting edge of the workpiece, while the high-speed airflow blows the molten metal away from the substrate, forming a narrow cutting seam. The CNC system automatically adjusts the cutting torch height by monitoring the arc voltage changes in real time to maintain optimal cutting conditions. For example, when the cutting thickness changes, the system will adjust the cutting torch height through arc voltage feedback signal to ensure stable arc length and avoid excessive cutting slope or slag hanging phenomenon. In addition, the system can dynamically adjust the cutting speed and gas flow rate based on material characteristics to achieve optimal cutting efficiency and quality.

3.3 Arc termination stage: Closing control of incision quality

The arc closing stage is the final stage of the cutting process, and its handling directly affects the quality of the cut end. Numerical control plasma cutting machines usually use advanced deceleration and arc voltage attenuation techniques to gradually reduce the cutting speed and current near the cutting endpoint, so as to slowly weaken the arc energy and avoid the accumulation or burning through of molten metal at the end of the incision. At the same time, the system can completely blow away the molten metal at the end of the incision by controlling the gas flow rate, ensuring a smooth and even incision.

4.Technological advantages and development trends

4.1 Technical advantages: high efficiency, precision, and strong adaptability

The CNC plasma cutting machine has become the preferred equipment in the field of metal processing due to the following advantages:

Efficiency: The cutting speed can reach 5-6 times that of flame cutting, especially suitable for large-scale production.

Accuracy: The cutting precision can reach ± 0.2mm, meeting the requirements of high-precision machining.

Adaptability: It can cut various conductive materials such as carbon steel, stainless steel, aluminum alloy, copper, etc., and is not limited by material thickness (the maximum cutting thickness can reach 300mm).

Flexibility: Supports cutting of any shape without the need for specialized molds, suitable for small batch and multi variety production.

4.2 Development Trends: Intelligence and Greening

With the advancement of Industry 4.0 and intelligent manufacturing, CNC plasma cutting machines are developing in the following directions:

Intelligence: Integrating sensors, the Internet of Things, and big data technology to achieve real-time monitoring of device status, fault warning, and remote maintenance.

High precision: Using laser positioning and visual recognition technology to improve cutting accuracy to the micrometer level.

Greenization: Optimize power efficiency and gas utilization, reduce energy consumption and emissions, and meet environmental protection requirements.

Modularization: Through modular design, rapid assembly and upgrading can be achieved to meet the personalized needs of different users.

The CNC plasma cutting machine achieves efficient and precise cutting of metal materials through a precise energy conversion mechanism, core component coordination, and cutting process control. Its technological advantages and development trends indicate that this equipment will play a more important role in the future manufacturing industry, promoting the transformation and upgrading of the metal processing industry towards intelligence and green direction. For enterprises, choosing a CNC plasma cutting machine that suits their own needs is not only the key to improving production efficiency and product quality, but also an important strategic investment for participating in global competition.

Language

▼

Language

▼

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com