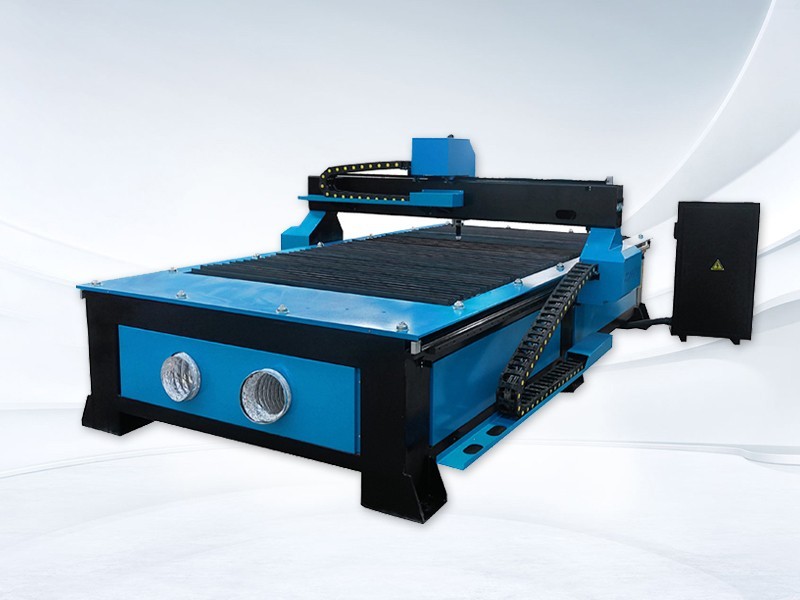

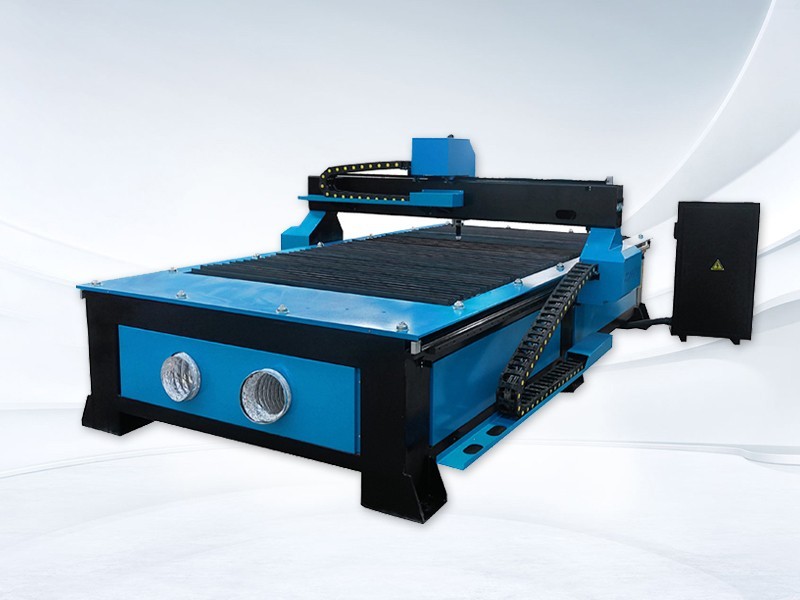

As a widely used cutting equipment in modern industry,CNC plasma cutting machines play an important role in metal processing and other fields due to their efficient and accurate cutting capabilities.However,due to the high voltage involved in its working process,once there is a leakage situation,it is highly likely to cause electric shock accidents,seriously threatening the safety of operators'lives.Therefore,it is crucial to take effective preventive measures to prevent electric leakage and shock in CNC plasma cutting machines.

1.Equipment selection and installation process

(1)Select qualified products

When choosing a CNC plasma cutting machine,it is essential to select products with legitimate production qualifications and reliable quality.To check whether the product has passed relevant safety certifications,such as China Compulsory Certification(CCC).Qualified products will strictly follow safety standards in the design and manufacturing process,using high-quality electrical components and insulation materials to reduce the risk of leakage from the source.

(2)Professional installation and debugging

The installation of equipment should be carried out by professional technicians.Before installation,it is necessary to ensure that the installation site meets the equipment requirements,such as a flat and dry ground,and no flammable or explosive materials around it.When connecting the power supply,use cables that meet the rated voltage and current requirements of the equipment,and ensure that the specifications and quality of the cables meet the standards.At the same time,proper grounding is required,and the grounding resistance should meet the specified requirements.Good grounding can effectively introduce leakage current into the ground and reduce the possibility of electric shock.After installation,comprehensive debugging and inspection should be carried out to ensure the normal operation of the electrical system of the equipment.

2.Daily operation standards

(1)Pre operation inspection

Before using the CNC plasma cutting machine,the operator must conduct a detailed inspection.Check if the electrical connections are secure,including power cords,plugs,sockets,etc.,and inspect for any looseness,damage,or aging.Check if the grounding device of the equipment is intact and if the grounding wire is tightly connected.In addition,the insulation performance of the equipment should be checked.An insulation resistance tester can be used to measure the insulation resistance of the equipment to ensure that it meets safety standards.

(2)Follow the operating procedures

Strictly follow the operating procedures of the CNC plasma cutting machine for operation.Before starting the equipment,ensure that all safety devices are in normal working condition,such as leakage protectors,emergency stop buttons,etc.During the operation,avoid operating the equipment with wet hands to prevent moisture from entering the electrical system and causing electrical leakage.At the same time,do not touch electrical components and live parts at will while the equipment is running.If debugging or maintenance is required,the power must be cut off first.

(3)Personal protective measures

Operators should wear appropriate personal protective equipment,such as insulated gloves,insulated shoes,etc.Insulated gloves and shoes can effectively block current and reduce the harm of current to the human body during electric shock.In addition,operators should wear dry and tidy work clothes to avoid increasing the risk of electric shock due to damp clothing.

3.Equipment maintenance and upkeep

(1)Regular maintenance plan

Develop a detailed equipment maintenance plan and regularly maintain and upkeep the CNC plasma cutting machine.The maintenance content includes cleaning the electrical parts of the equipment,removing dust and debris,and preventing dust accumulation from causing short circuits or leakage of electrical components.Check the appearance and performance of electrical components.If any abnormal conditions such as heating,discoloration,or odor are found,they should be replaced in a timely manner.

(2)Replace aging components

With the use of equipment,electrical components will gradually age and insulation performance will decrease.Therefore,it is necessary to regularly check the service life of electrical components and replace aging parts such as wires,cables,switches,etc.in a timely manner.When replacing components,choose products with the same specifications and reliable quality as the original components to ensure the electrical safety of the equipment.

(3)Professional maintenance services

When equipment malfunctions and requires maintenance,professional repair personnel should be contacted.Professional maintenance personnel have rich experience and professional knowledge,can accurately determine the cause of faults,and adopt correct maintenance methods.During the maintenance process,it is necessary to strictly follow the maintenance manual to avoid equipment leakage caused by improper maintenance.

Preventing electric leakage and shock in CNC plasma cutting machines requires starting from multiple aspects such as equipment selection and installation,daily operation standards,and equipment maintenance and upkeep.Only by fully implementing various preventive measures can the probability of electric leakage and shock accidents be effectively reduced,ensuring the safety of operators and the normal operation of equipment.

Language

▼

Language

▼

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com