Language

▼

Language

▼

More Language

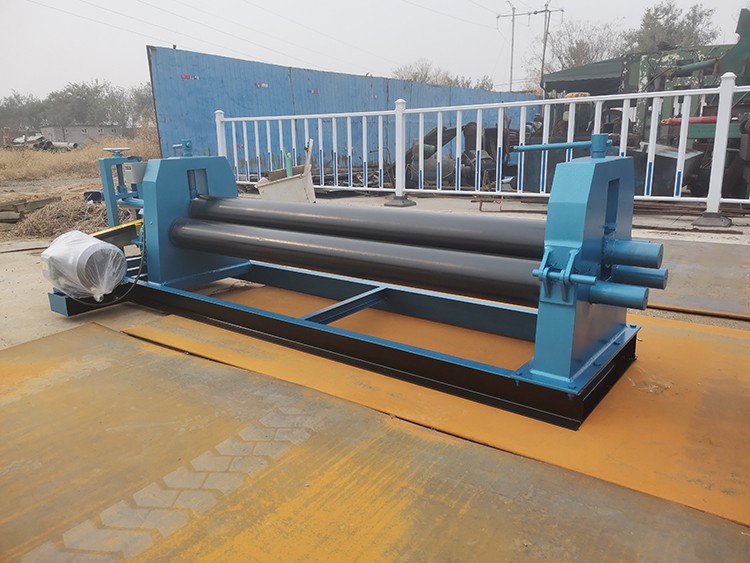

Becoming the customer's preferred brand, thanks to over a decade of relentless efforts in plate rolling machine manufacturing, we present the following guide to identifying common leakage points in plate rolling machine hydraulic systems:

Over extended periods of operation, plate rolling machine hydraulic systems may experience leakage issues due to seal aging, mechanical vibration, or improper installation. Leakage can lead to hydraulic oil loss, reduced system pressure, and even impact equipment precision and stability. Timely identification and resolution of leakage points are critical to ensuring normal equipment operation. The following are methods for identifying common leakage points in the hydraulic system of a plate rolling machine and recommendations for their resolution.

1, Hydraulic cylinder leakage

The hydraulic cylinder is the main actuator of the rolling machine. Leakage typically occurs at the piston rod seal or the cylinder end cap.

Piston rod seal leakage: If there is an oil film or oil dripping on the piston rod surface, it may be due to seal ring wear or piston rod scratches. During inspection, observe whether the piston rod is smooth and free of rust or wear. If the seal ring is aged, replace it with a seal of the same specification; if the piston rod is damaged, it can be polished for repair or replaced.

Cylinder end cover leakage: The end cover gasket may leak due to long-term pressure deformation or loose bolts. Check whether the bolts are tight and the gasket is intact, and replace the oil-resistant gasket if necessary.

2, Hydraulic pipe and joint leakage

High-pressure oil pipes and joints are prone to leakage, which can be divided into two types: hard pipe joints and soft pipe joints.

Hard pipe joint leaks: Metal pipe joints typically use tapered threads or flange connections. If the seal is poor or the threads are damaged, oil leakage may occur. During inspection, ensure that the joint is securely tightened and that the sealing tape or O-ring is intact.

High-pressure hose leaks: Oil leaks at hose joints may be caused by loose crimping or aging of the hose. If oil leakage is detected at the joint, inspect the crimping area for secure fastening and check the outer layer of the hose for cracking or bulging. If aging or damage is found, replace immediately.

3, Hydraulic valve block leakage

Leakage in hydraulic valve blocks (such as directional control valves, relief valves, etc.) usually occurs at the valve body joint or solenoid installation site.

Valve body joint leakage: The seal ring between the valve block and valve body may be insufficiently compressed or have failed due to aging. After disassembly, check whether the seal ring is deformed and whether the seal groove is flat. When installing, tighten the bolts to the standard torque to avoid uneven force.

Electromagnetic valve seal leakage: Some electromagnetic valves have sealing rings at the push rod, which may wear out after long-term use. If oil leakage is found on the electromagnetic valve housing, check whether the push rod seal is intact and replace it if necessary.

4, Hydraulic pump and motor leakage

Hydraulic pump and motor leakage mainly occurs at the shaft seal and housing joint.

Shaft seal leakage: If oil leaks from the shaft end of the pump or motor, it may be due to shaft seal wear or excessive bearing clearance. Shut down the machine and check whether the shaft seal lip is damaged or the shaft neck is worn. When replacing the shaft seal, pay attention to the installation direction to avoid installing it backwards.

Housing joint surface leakage: The end cover gasket of the pump or motor may have aged due to vibration or high temperatures. If oil is leaking from the joint surface, clean the residual adhesive and replace the gasket. When installing, tighten the bolts evenly.

5, Fuel tank and accessory leaks

Auxiliary components such as fuel tanks, oil filters, and coolers may also leak.

Fuel tank leaks: Check welds for cracks, observe whether the window seal is aged, and check whether the drain plug is tightened. If the fuel tank vent is blocked, the internal pressure may increase and exacerbate the leak. The vent device should be cleaned regularly.

5, Fuel tank and accessory leaks

Auxiliary components such as fuel tanks, oil filters, and coolers may also leak.

Fuel tank leaks: Check welds for cracks, observe whether the window seal is aged, and check whether the drain plug is tightened. If the fuel tank vent is blocked, the internal pressure may increase and exacerbate the leak. The vent device should be cleaned regularly.

6, Accumulator leakage

Accumulators are used to stabilize system pressure, and leaks may occur in the airbag or inflation valve.

Airbag rupture: If gas is escaping from the accumulator oil port, the airbag may be damaged and need to be replaced.

Inflation valve leakage: Regularly check the nitrogen pressure. If the pressure drops too quickly, it may be due to poor inflation valve sealing, which needs to be repaired or replaced.

Troubleshooting and maintenance recommendations

Visual inspection: Regularly check the equipment surface for oil stains, focusing on the hydraulic cylinder, pipe joints, and valve assembly.

Pressure testing: Leakage points are usually more obvious when the system is pressurized, but safety precautions must be observed.

Regular maintenance:

Check the condition of the seals every three months and replace any parts that have deteriorated.

Clean the oil tank and replace the filter element annually to prevent impurities from accelerating seal wear.

Recording and analysis: For parts that leak repeatedly, record the cause of the failure and determine whether it is a design or installation issue.

Leakage issues in the hydraulic system of a plate rolling machine are often caused by aging seals, mechanical vibration, or improper installation. By systematically inspecting key components such as hydraulic cylinders, piping, valve assemblies, and pump motors, leakage risks can be effectively reduced. Upon discovering a leak, temporary measures or shutdown repairs should be selected based on the severity of the issue to ensure long-term stable operation of the equipment.

If you are interested in plate rolling machines, please contact us.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com