Language

▼

Language

▼

More Language

一、Bending machine

1,Machine model name

Model: WC67K-100Tx3200 NC hydraulic bending machine

Image(For reference only):

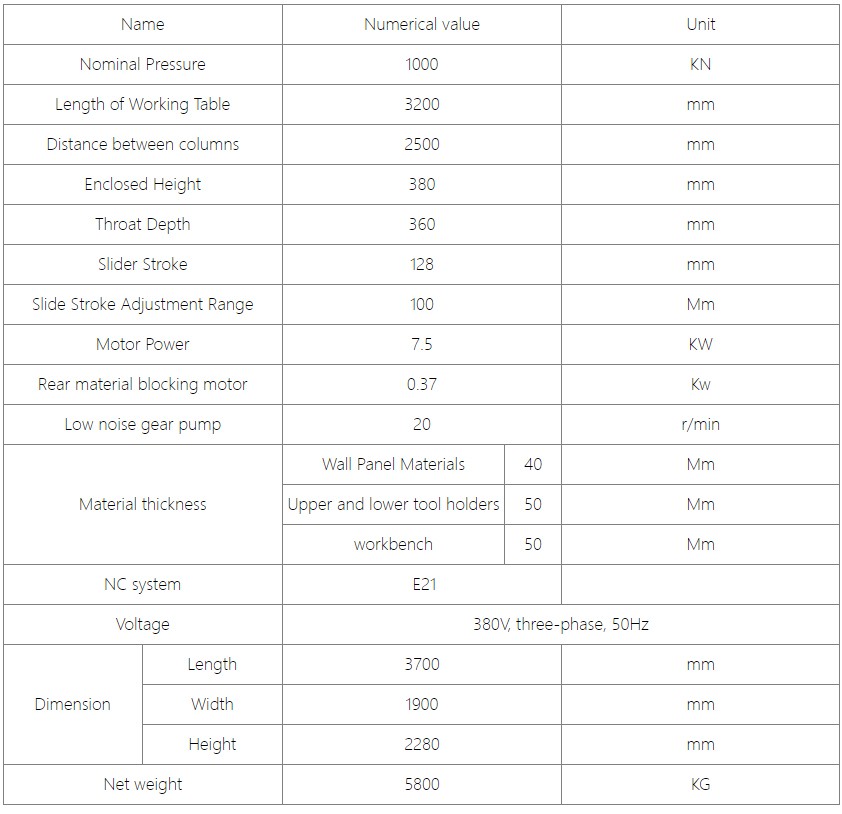

2, Main parameters

❄The size and weight of the machine are estimated values for reference only, and the actual products produced shall prevail

❄Our machine's standard voltage is 380V, three-phase, 50Hz. If the voltage is different, please let us know and the price may change.

3, Product Structure and Design

1. Computer-aided optimization design employing UG (Finite Element) analysis methodology.

2. Machine body constructed with integral steel plate welded structure, delivering excellent strength, rigidity, and vibration resistance.

3. Internal stress relief processed using German technology.

4. Entire frame undergoes sandblasting for rust removal and is coated with anti-corrosion paint.

4, Performance Features

1. Hydraulic upper transmission ensures smooth and reliable operation.

2. Features rapid approach, pressurization, depressurization, and rapid retraction functions.

3. Slider synchronization employs forced torque shaft and built-in hydraulic cylinder mechanical stops for smooth and reliable operation.

4. Upper slider equipped with wedge-type deflection compensation device; effectively compensates for slider and worktable deflection to ensure folding precision.

5. Slider stroke and backgauge distance controlled via electric digital display with push-button operation.

6. The torsion shaft synchronizes the balance of two hydraulic cylinders, ensuring precise angles on both sides.

7. Standard upper/lower right-angle molds are available, with customization possible per client requirements.

5, Hydraulic System

The advanced integrated hydraulic system minimizes piping installation, ensuring high reliability and safety during machine operation.

6, Electrical Control System

1. Electrical components and materials comply with international standards, offering safety, reliability, and extended service life.

2. This machine operates on 50Hz, 380V three-phase four-wire power supply. The machine's motor uses three-phase 380V. The control transformer employs two-phase 380V. The output from the control transformer supplies the control circuits, with 24V dedicated to rear stop control and electromagnetic directional valves. The remaining 24V power supplies other control components.

3. The machine's electrical cabinet is located on the right side of the machine tool. All machine operation controls, except the foot switch, are centralized on the button station of the right-side suspended arm. Each operational control element's function is indicated by its corresponding pictorial symbol above it.

7, Front and rear material blocking

1. Front stopper: placed in front of the workbench and adjustable.

2. Rear stop material: Installed behind the workbench, the adjustment of the rear stop material is driven by a 0.55KW electric motor, and after gear reduction, it is driven by a screw The required size can be adjusted by positioning or directly pressing "+" or "-" in the operating system, and manual fine-tuning is provided, making it convenient and reliable to adjust the rear stopper.

8,Standard Machine Accessories

1. Adjustment Screws 4 pcs

2. Washers 4 pcs

3. Oil Gun 1 pc

4. Foot Switch 1 set

7.Product Operation Manual 1 copy

9,Main configurations

After sales service:

1、If there is any problem in the use process, please contact us and we will respond within 24 hours

2、 Warranty for 1 year. Within 1 year, if there is a malfunction due to the machine's own problems, we can provide free accessories. (expect for faults caused by no abiding by the relevant operationregulations, or by force injury)

Payment:By T/T,100% Full payment shipping

Delivery time: no stock available, production takes about 20 working days

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com